Electric dip

coating systems

Electric dip coating systems

Electric dip coating is an electrochemical process for coating metals that can be used for all submersible workpieces and is reckoned to be of particularly high quality, resource-saving and environmentally friendly. The paint ensures a hard-wearing surface with a very high level of corrosion protection and is used particularly in vehicle construction as well as in agriculture and forestry.

Depending on the polarity of the workpiece, electrocoating is divided into cathodic dipping (CDC system; workpiece acts as cathode) and anodic dipping (ADC system; workpiece acts as anode).

Advantages of coating

using electric dip coating

-

Resource- and environmentally friendly painting process

-

CDC and ADC systems

-

Even coating of the entire workpiece

-

Robust surface paint

-

High corrosion protection

-

Also suitable for complicated shapes with cavities

-

Can be combined with various top coats

-

High level of automation

The components are first cleaned in an immersion pretreatment line. During electric dip coating, the entire surface of the components is covered with an even film of paint. No shadows are produced, and even cavities or edges are coated cleanly and evenly. Following the painting process, the coating is sealed at approx. 180 - 220 °C and can subsequently be combined with other painting systems.

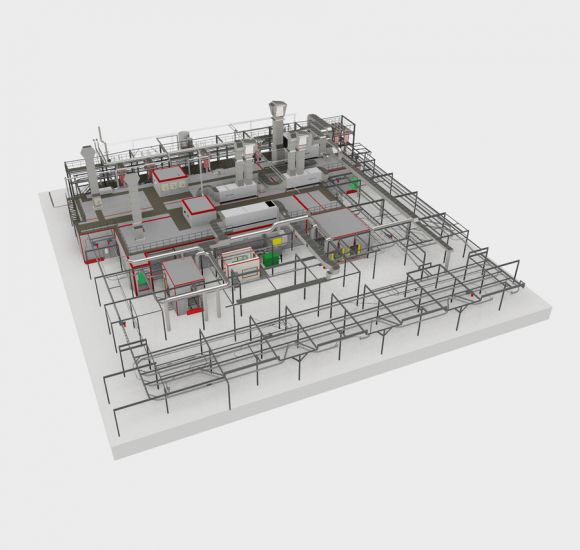

Within the dip coating segment, we supply conventional dip coating systems as well as CDC systems and ADC systems, including all peripherals, such as cycle lifting systems, ultrafiltration, VE rinsing and exhaust air purification. We rely on well-known manufacturers for our proven anolyte systems, dialysis cells and ultrafiltration components.

Depending on customer needs, a powder coating line can also be integrated into the system concept.

AFOTEK designs and develops state-of-the-art systems for CDC and ADC dip coating, tailored to the needs and components of customers. Particular attention is paid to the energy concept and heat recovery measures so that the system operator can operate his system cost-efficiently.

The control and safety technology of the dip coating systems are also made by AFOTEK, thus guaranteeing total system support. When controlling the systems, AFOTEK relies on innovative Siemens S7 technology including TIA Portal and works with a digital system twin to visualise the control system, which makes error detection and elimination extremely easy and minimises downtimes.

Specialisations

at a glance

Automation and digital solutions

Ultra-modern and intelligent system solutions ensure that painting system operators can work profitably. In addition to transparent processes and digital documentation, robotic painting systems and handling robots ensure cutting-edge system technology in accordance with the Industry 4.0 standard. Interfaces to upstream and downstream ERP and/or MES systems round off the innovative control concept.