THE PROFESSIONAL FOR

BIOLOGICAL AIR PURIFICATION SYSTEMS

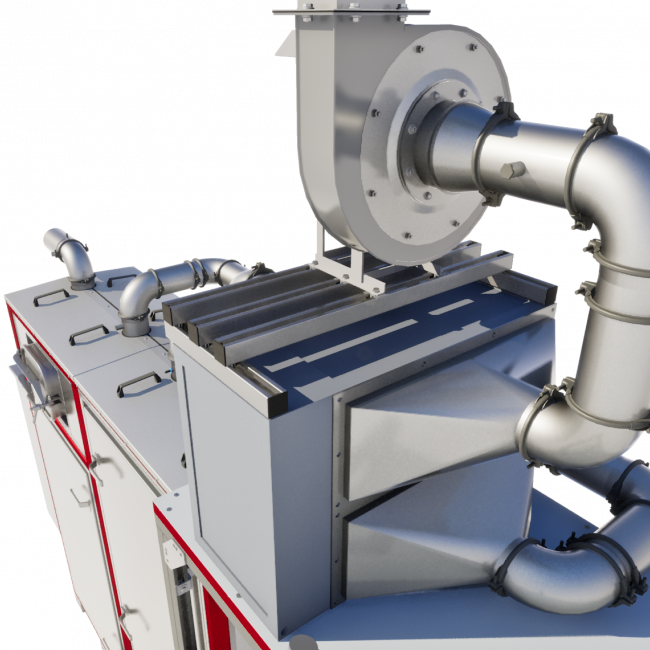

To protect the environment, the pollutants from gases and vapours produced during painting must be cleaned before exhaust air is released into the atmosphere. Since thermal cleaning systems are neither emission-free nor energy-saving, biological exhaust air purification using microorganisms is the ideal solution for removing pollutants from high exhaust air flows in a cost-efficient and environmentally friendly manner.

Advantages of AFOTEK's biological exhaust air purification systems

-

Environmentally friendly process to minimise pollutants (biofilter)

-

Low space requirement (optimal use of operating space)

-

The system can also be placed outside the production hall

-

Individually configurable (modular principle)

-

Alignment with customer needs (flexible adjustment of system capacity, system size and volume flows)

-

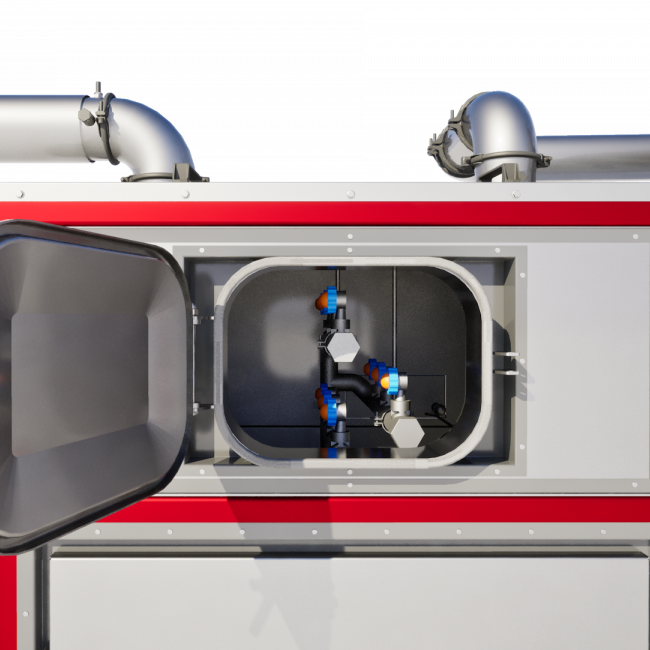

Operation and regulation of pumps, fans, sensors and optional heating

-

Low maintenance effort thanks to fully automated control technology (control cycles and maintenance times are significantly reduced)

-

Situational equipping of heat recovery systems possible

Two cylindrical reactor towers, which are filled with a special, structured carrier material, are a key component of the biological exhaust air purification system. These structured packings are exposed to a suspension of water, microorganisms and chemicals, resulting in the formation of a biofilm

The active principle of biological exhaust air purification is based on the use of aerobic microorganisms, which convert the incoming air pollutants into harmless end products, such as carbon dioxide and water. The active principle is based on the one hand on the flow of structured packings and the conversion of dissolved pollutants in a storage tank.

Biological exhaust air purification is designed specifically for the individual application. A system concept is developed in collaboration with the customer, which can be optimally integrated into existing system concepts.

SPECIALISATIONS

AT A GLANCE

Automation and digital solutions

Ultra-modern and intelligent system solutions ensure that painting system operators can work profitably. In addition to transparent processes and digital documentation, robotic painting systems and handling robots ensure cutting-edge system technology in accordance with the Industry 4.0 standard. Interfaces to upstream and downstream ERP and/or MES systems round off the innovative control concept.